PRODUCTS

Where architecture meets

sustainability

Pre-Engineered Building (PEB) Structures

Pre-Engineered Building (PEB) structures represent a revolution in modern construction, offering versatility, efficiency and durability. These structures are meticulously designed and fabricated off- site, with all components manufactured to precise standards. The result is a seamless integration of components on-site, reducing construction time significantly.

PEB structures excel in various applications, from industrial and commercial spaces to warehouses and recreational facilities. They are tailored to meet specific requirements, offering a range of customization options in terms of design, layout and finishes. With an emphasis on cost- effectiveness, PEB structures often involve fewer materials and labor compared to traditional construction methods, making them an environmentally friendly choice.

Designed to withstand varying weather conditions, seismic forces and other challenges, PEB structures showcase exceptional strength and longevity. These structures combine engineering precision and technological advancements, resulting in aesthetically pleasing, functional and reliable spaces that fulfill the demands of modern construction projects.

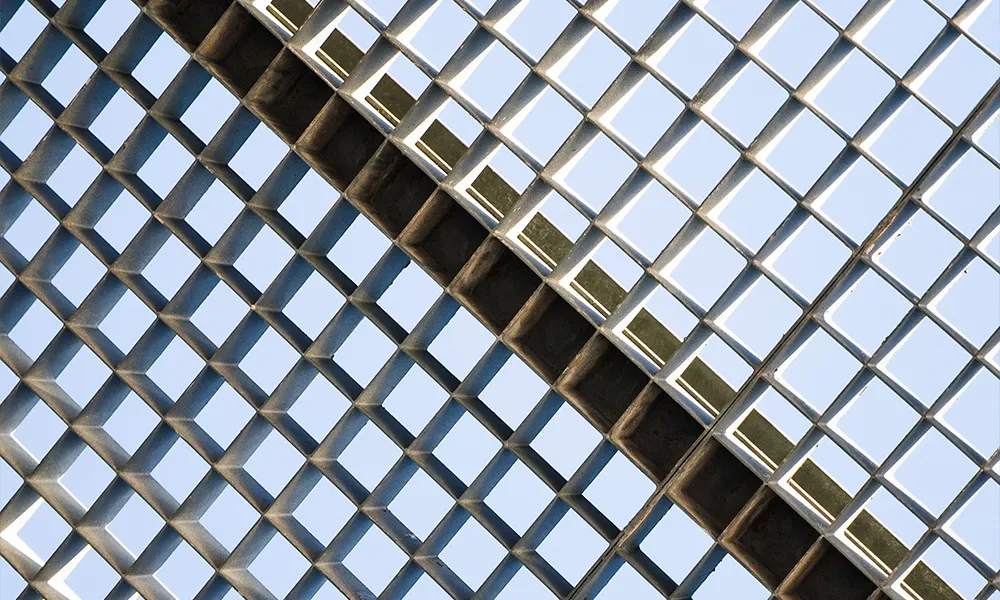

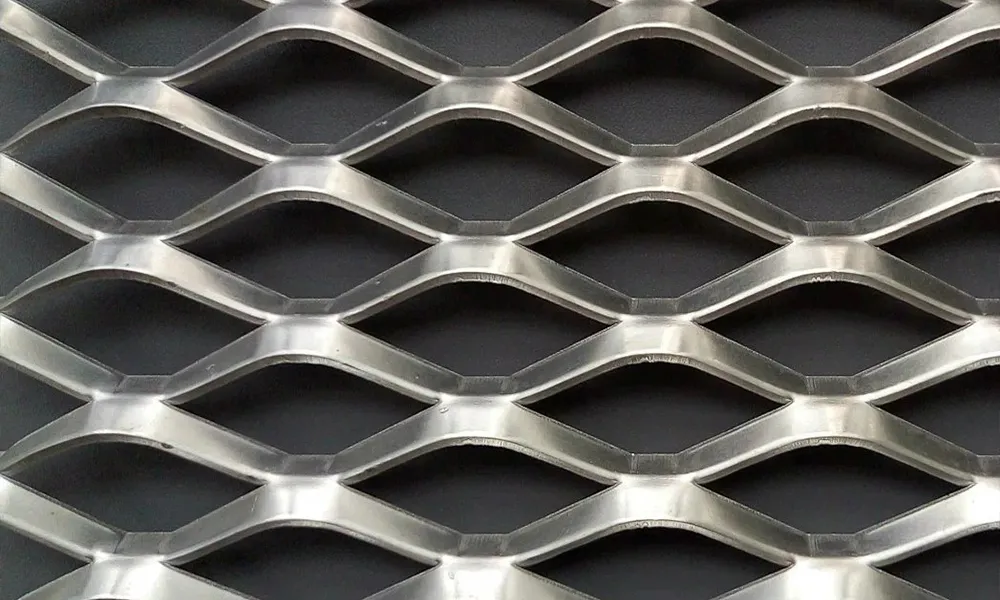

- E-Mesh Expanded Mesh

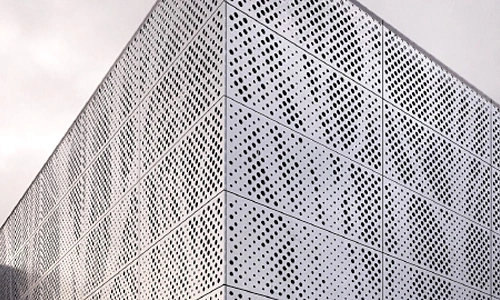

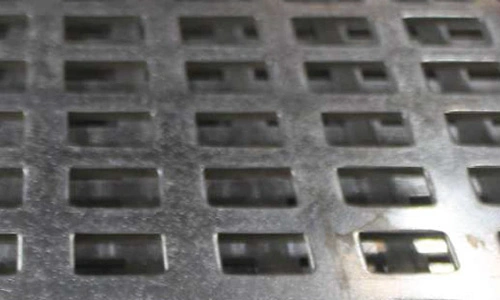

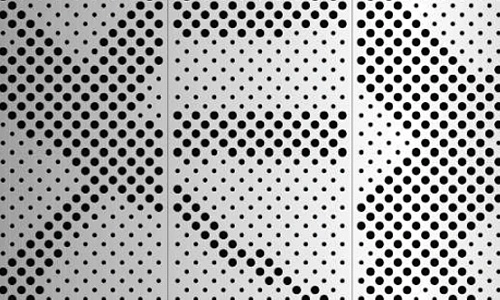

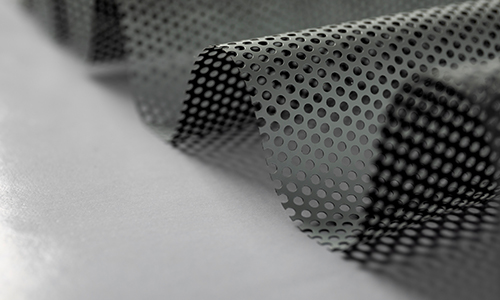

- Perforated Panels

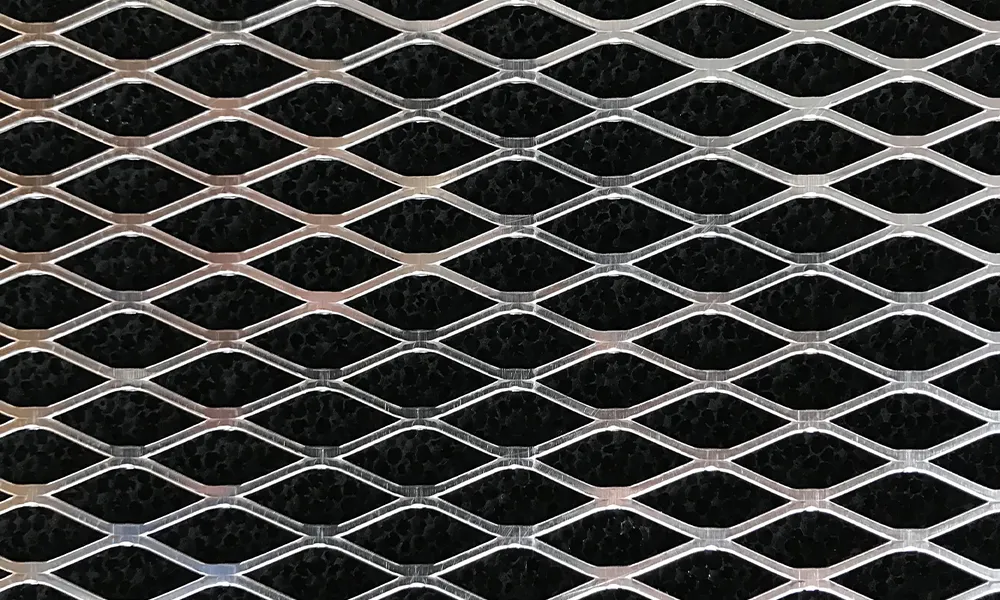

- E - MESH Flat Rolling

- Mashrabiya Designs

- Purlin

- Comet - ES 110

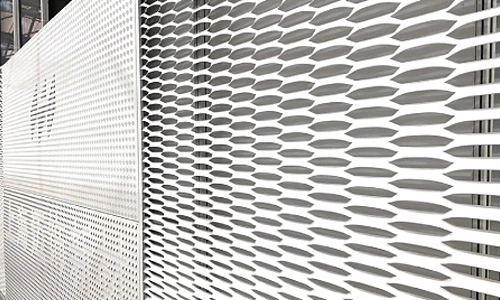

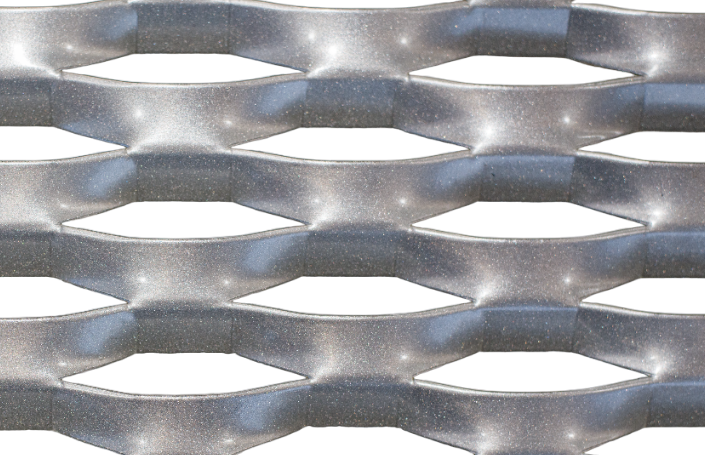

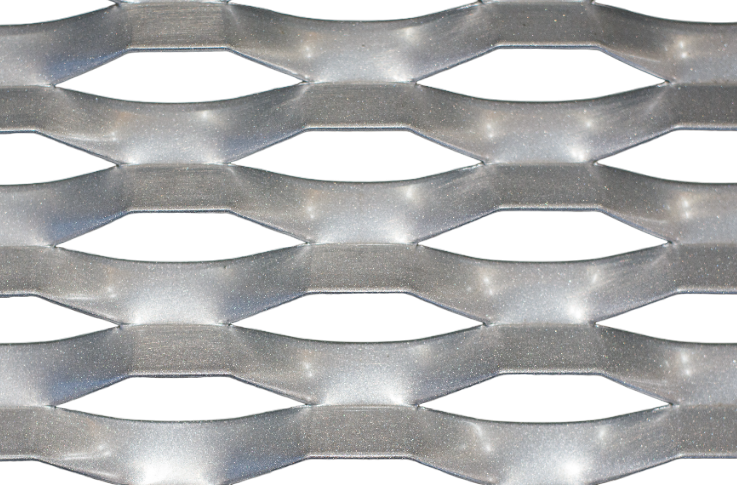

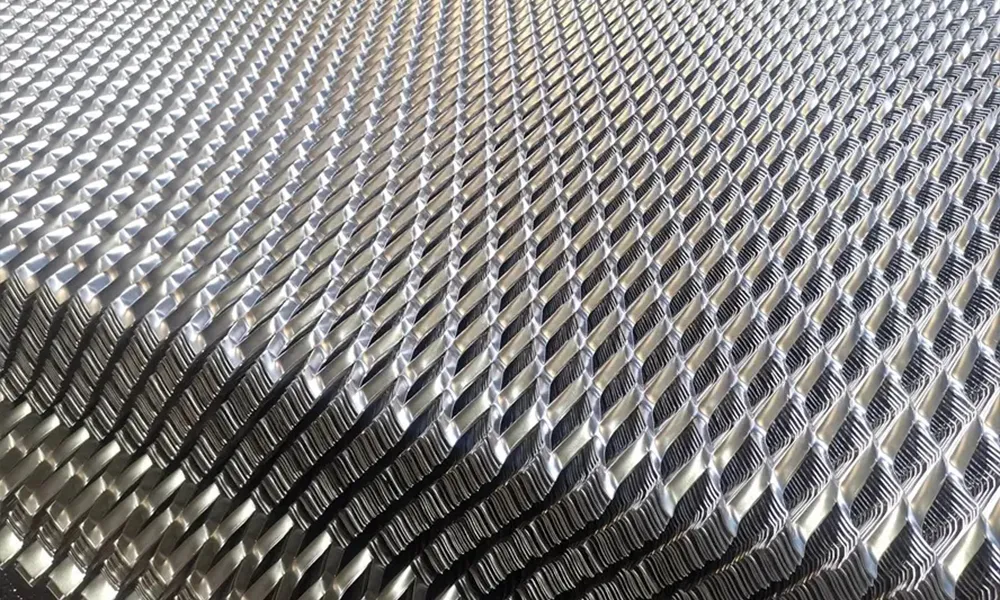

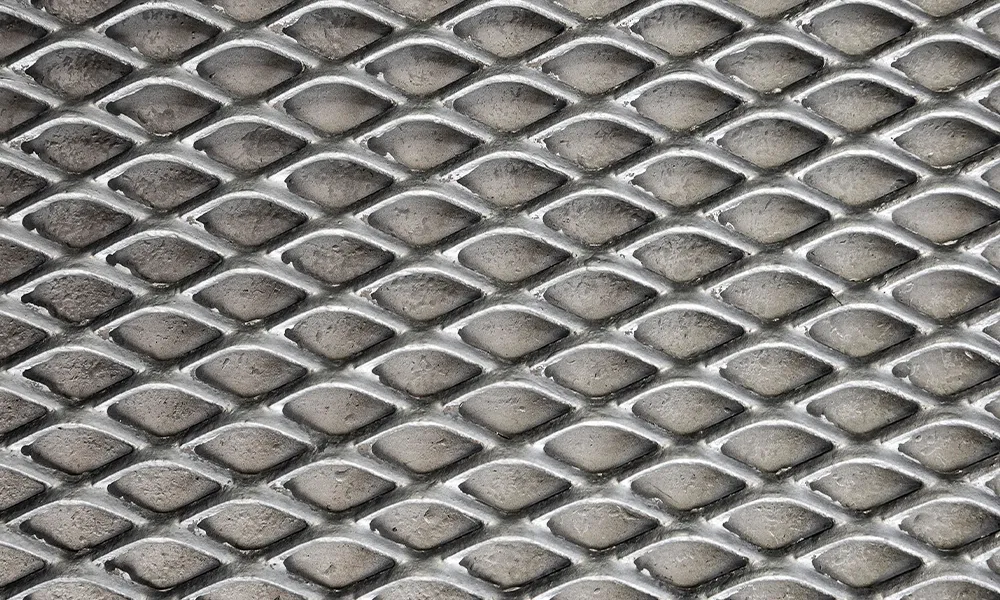

Commonly utilized for architectural exterior cladding, ceilings, fences, driveways, and grilles. Expanded metal mesh offers durability and strength surpassing lighter wire mesh. Its small openings enable airflow, water passage, and light transmission while barring larger objects. Unlike standard sheet metals, exposed edges enhance traction, making it ideal for display stands and drain covers.

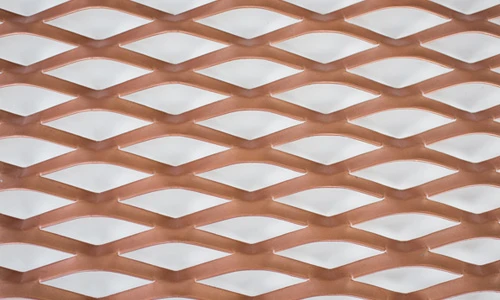

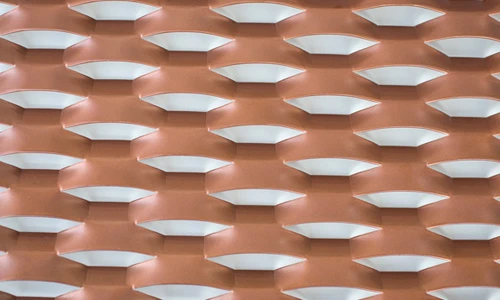

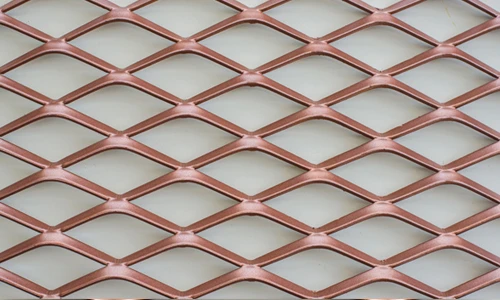

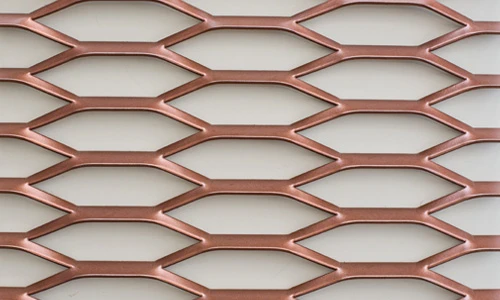

E - MESH expanded metal mesh has four architectural views

A - side in the direction of expansion

A - The side opposite to the direction of expansion

B-Side in the direction of expansion

B-Side against the direction of expansion

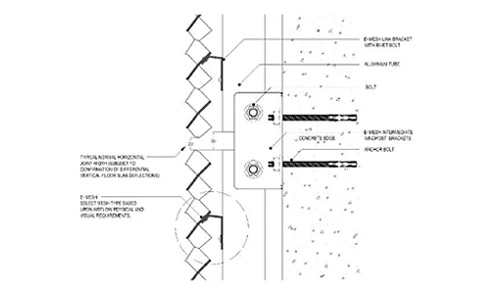

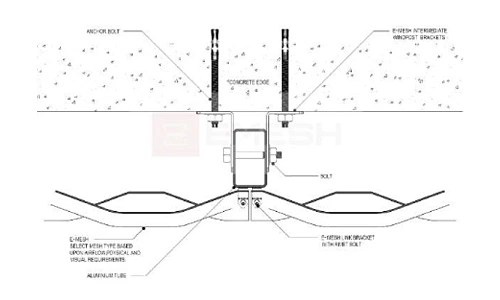

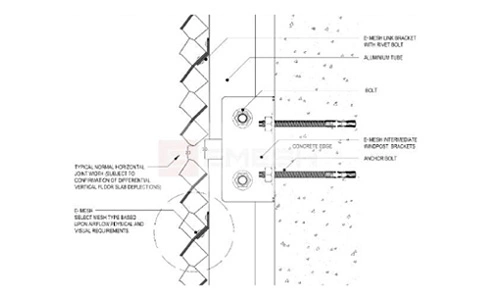

E Mesh tipical angle fixing method

Top view

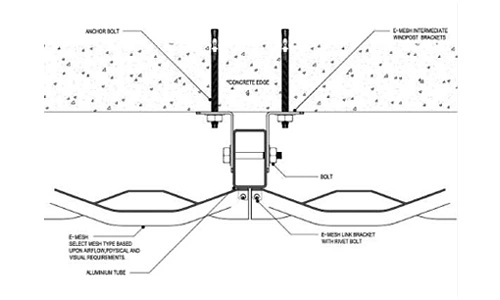

E Mesh L angle fixing method

Top view

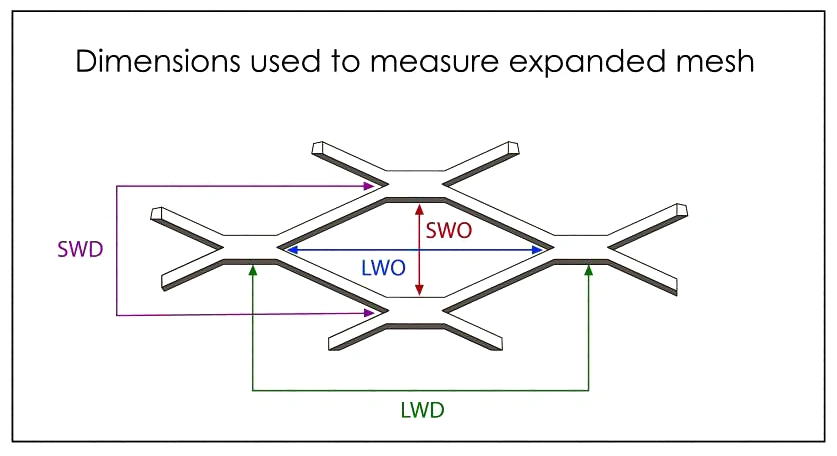

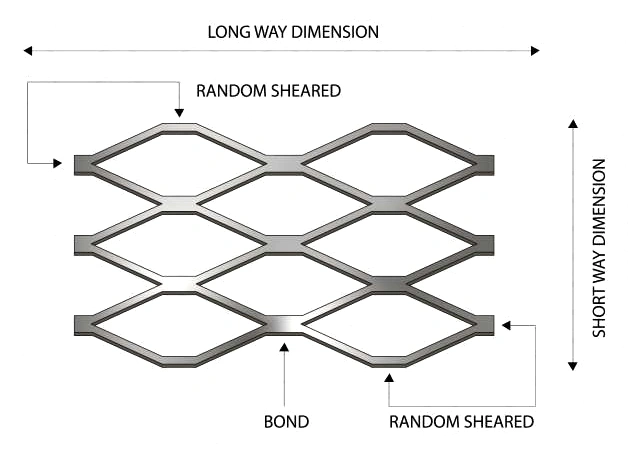

Dimensions used to measure expanded mesh

LWD — Long way dimension of the expanded mesh.

SWD — Short way dimension of the expanded mesh.

LWO — Long way opening of the expanded mesh.

SWO — Short way opening of the expanded mesh.

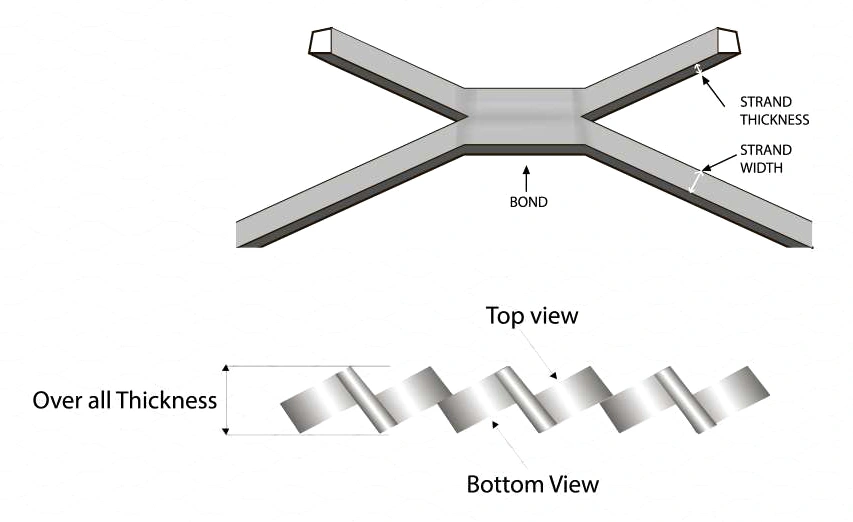

Strand Width - Length fed between the upper and lower tooling to produce the mesh.

Strand Thickness - The thickness of the material used to produce the standard material is the original thickness. It is also the thickness of the material after flattening the expanded mesh.

Bond - The intersection of the extended punched expanded mesh connections. It is sometimes called as a joint.

Overall Thickness - Expand the thickness of the mesh when laying on a flat surface. In the case of flat materials, the strands and the total thickness are the same.

Perforated metal, commonly known as perforated sheet or screen, is crafted by manually or mechanically stamping, utilizing CNC technology or employing laser/water jet cutting to form holes of varying sizes, shapes and patterns. The materials employed for creating perforated sheet metal encompass stainless steel, cold rolled steel, galvanized steel, brass, aluminium and other choices.

Perforated Panel

Square hole perforation

Hexagonal perforation

Round hole perforation

Slot hole perforation

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

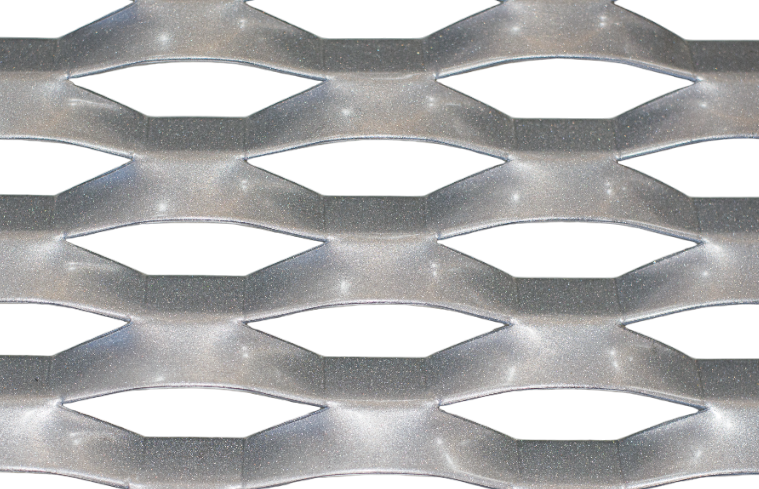

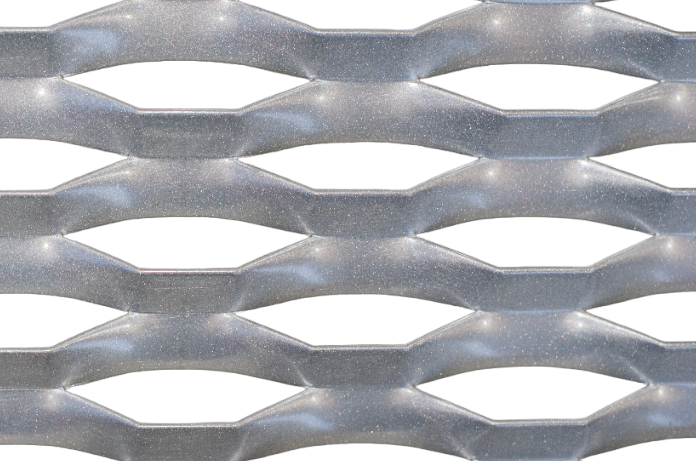

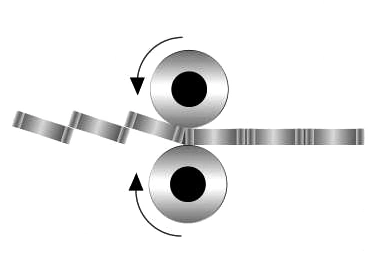

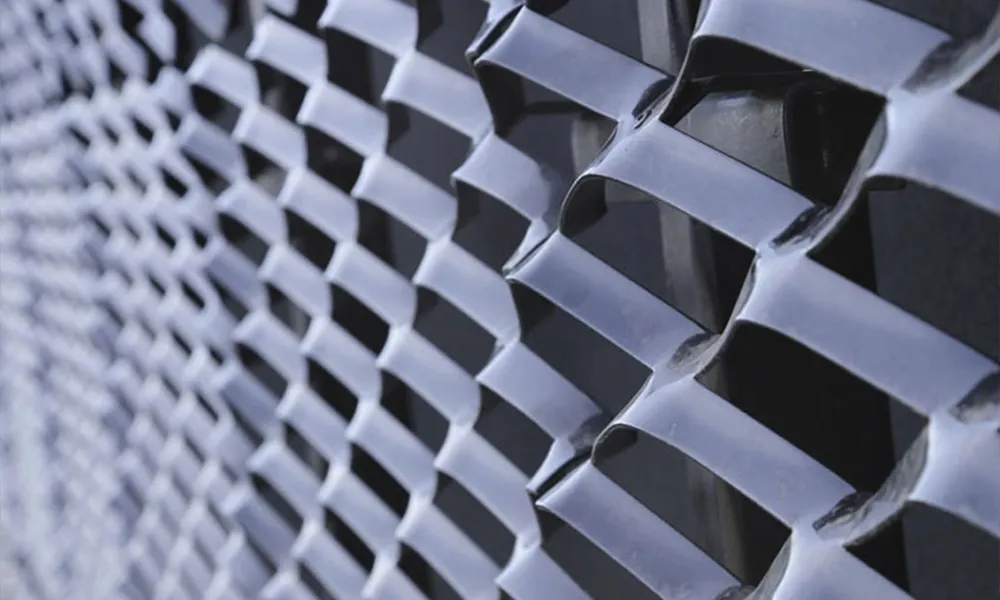

Flat rolling of expanded mesh is a supplementary procedure aimed at decreasing the overall thickness of the mesh. This flattening process encompasses four primary stages, with specific approaches differing among various Expanded Mesh manufacturers.

Diagram of flat-rolling process

Expanded Metal before flat rolling

Expanded metal after flat rolling

Random Shearing: Results in open diamond design and angle, leaving jagged edges and prongs in most cases. A closer tolerance is obtained at a normal mill tolerance for standard and flattened expanded metal of +/- 1.58 mm and +/- 25.4 mm on shearing.

Bond Shearing: Results in closed diamond design and angle, eliminating jagged edges and prongs. Shearing cuts through expanded metal at center of bond, where strands intersect. Standard expanded metal should not be bond sheared SWD. SWD and LWD tolerances are greater at +/-1/2 design size.

Mashrabiya, a blend of islamic window screen and classic jalousie, embodies spirituality, aesthetics and utility, reflecting local cultural essence. Whether in commercial or residential settings, the mashrabiya serves multifarious roles, encompassing light modulation, airflow control, temperature reduction, humidity enhancement and ensuring substantial privacy.

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

E Mesh metal is a dedicated roll-forming facility equipped with modern machinery to perform the job needed for tomorrow’s landscape. Run by a team of highly trained production executives, the state-of-the-art facility produces an extensive range of precision-cut C and Z purlins.

The company ensures customer satisfaction through stringent quality control processes governed and System as well as the Factory Production Control

Range of products and services

- Hot dipped galvanized High Tensile Steel C and Z purlins

- Section sizes from 75mm – 350mm

- Base Metal Thickness (BMT) – 1.6mm, 2mm, 2.5mm and 3mm

- Bridging pieces

- Design calculation based on IS Standard

Application of C & Z purlins

At E-Mesh metal, we understand the liberal designs of architects and engineers. Our C and Z purlins are roll-formed and precision-cut for a multitude of uses that includes, but is not limited to;

- Structural supports

- Single bay buildings

- Recessed roofs or walls

- Tower structures

- End walls

- Interior supports of multi-bay buildings

Our purlins are a lightweight & efficient economical support system for framed structures.

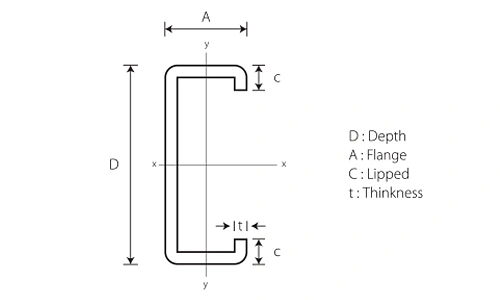

C Purlins - Section

- C purlins have equal flanges and are suitable for simply supported spans. C purlins are non-overlapping.

- Non-standard orders are available upon request.

C Purlins - Profile

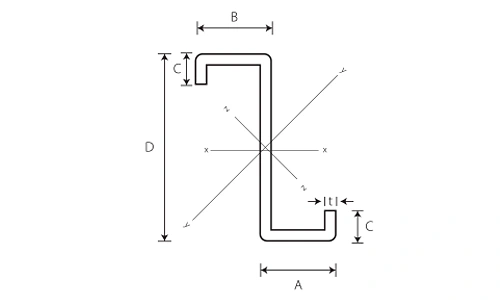

Z Purlins - Section

Z purlins feature one broad and one narrow flange so that two Z purlins of the same size fit snugly together. Z purlins are ideal for lapping to achieve higher strength for the same section installed in single spans.

Z Purlins - Profile

Material Specifications

Hot Dipped Galvanized High-Tensile Steel

- Designed accordence with IS 277: 2018 and also conform to IS 875

- Minimum yield stress 450 MPa.

- Available in 80 and 120 GSM

- Base metal thickness: 1.6mm, 2mm, 2.5mm, 3mm

*Zinc coating grade: Z350 (350g/m2) class 2

| Purlin Type | Thickness (mm) | D(mm) | A(mm) | C(mm) |

|---|---|---|---|---|

| C & Z 150 | 1.6 & 2 | 150 | 62 | 18 |

| C & Z 200 | 1.6 & 2 | 200 | 62 | 18 |

| C & Z 250 | 2 & 2.5 | 250 | 62 | 18 |

| C & Z 300 | 2 & 3 | 300 | 62 | 18 |

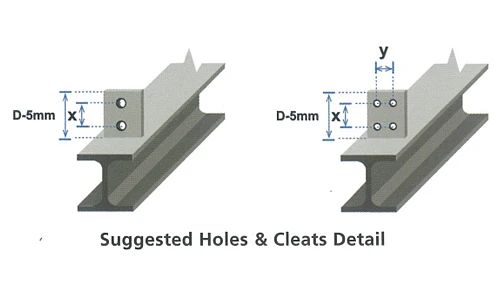

Hole Punch & Cleat Details

- E-Mesh Metal’s C and Z purlins are supplied with holes punched (to builder’s requirements) with recommended holes to match cleat details (see illustration below).

- The purlins are designed based on the web to cleat connection of sections.

- Please use purlin detailing sheet when placing an order.

Note:-

- It is necessary to have the top flange of the purlins to point up the slope. This minimizes any rotational tendencies of the purlins.

- D: purlin depth.

- 10 standard hole punch per piece. Additional hole punch subject to additional charges.

Purlin puch hole

| C100 – 300 | Z150 – 300 | ||

|---|---|---|---|

|

|

|

|

| Round | Elongated | Round | Elongated |

| Ø14 | Ø14 x 26 | Ø14 | Ø14 x 26 |

| Ø16 | Ø16 x 26 | Ø16 | Ø16 x 26 |

| Purlins Depth (mm) | X (mm) | Y (mm) |

|---|---|---|

| 150 | 60 | 80 |

| 200 | 110 | 80 |

| 250 | 160 | 80 |

| 300 | 210 | 80 |

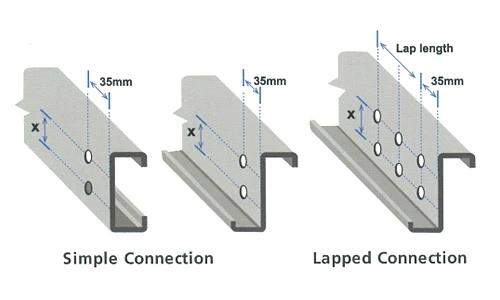

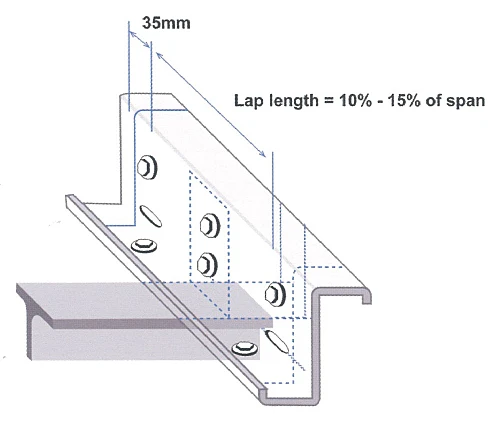

Lapping Details

To provide sufficient structural continuity, each end of the lap requires one bolt through the webs, nominal length is the distance between bolt centers at the end of the laps. Laps vary in length with both section size and span, minimum lap should be 10% of the span.

Bolt Details

Bolts are usually M14, M16 (grade 4.6)

Application

C purlins can be used in single or continuous spans but cannot be lapped. Z purlins can be used in single or continuous spans (lapped or unlapped). Lapped continuous spans will increase purlins loading capacity.

Custom cut

E-Mesh high tensile purlins are available in custom-cut lengths, Special transportation arragement and on-site handling equipments are required for purlin lengths more than 12m.

Packing & Transportation

E-Mesh purlins are packed in bundles with weight generally less than 1500kg and strapped with metal strips. Special packing for export requirements are provided upon request.

Table 1 Dimensions -Hot Dipped Galvanized High-Tensile Steel C Purlins

| Purlin Type | Product Code | Thickness (mm) | D (mm) | A (mm) | C (mm) | Unit Weight (kg/m) |

|---|---|---|---|---|---|---|

| 100 | 40 | 80 | 80 | 80 | 80 | 80 |

| 125 / 150 | 60 | 80 | 80 | 80 | 80 | 80 |

| 250/225 | 110 | 80 | 80 | 80 | 80 | 80 |

| 250 | 160 | 80 | 80 | 80 | 80 | 80 |

| 300 | 210 | 80 | 80 | 80 | 80 | 80 |

| 350 | 250 | 80 | 80 | 80 | 80 | 80 |

Table 2 Dimensions -Hot Dipped Galvanized High-Tensile Steel Z Purlins

| Purlin Type | Product Code | Thickness (mm) | D (mm) | A (mm) | C (mm) | Unit Weight (kg/m) |

|---|---|---|---|---|---|---|

| Z150 | Z15016 Z15020 |

1.6 2 |

150 150 |

62 62 |

18 18 |

3.8936 4.867 |

| Z200 | Z20016 Z20020 |

1.6 2 |

200 200 |

62 62 |

18 18 |

4.5216 5.652 |

| Z250 | Z25020 Z25025 |

2.5 2 |

250 250 |

62 62 |

18 18 |

6.437 8.04625 |

| Z300 | Z30020 Z30030 |

2 3 |

300 300 |

62 62 |

18 18 |

7.222 10.833 |

This kind of mesh is particularly suitable for the creation of roof-gardens. The hole diameter and the material have been carefully chosen order to let the expanded metal and the plants live together. Technology and nature, a possible match.

Technical Details

LWD (mm) – 110

SWD (mm) – 40

Strand Width – 16

Strand Thickness – 1.89

Open Area Percentage – 33%

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

- Shale - EL 170

- Supernova - EM 240

- Aurora - EM 150

- Venus - ES 225

- Polaris - EL 60

- Cosmic - EM 72

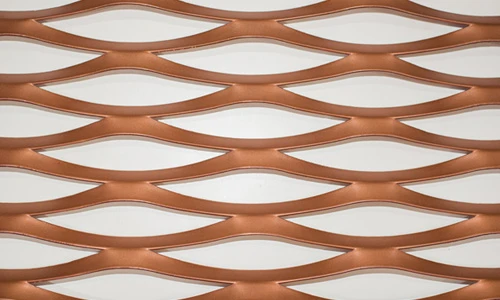

It is suitable for every type of facades, the right mix between mesh

dimensions and percentage of open area. Various types of finishing such as RAL and colored anodization add value to your metal covering.

Technical Details

LWD (mm) – 170

SWD (mm) – 50

Strand Width – 20

Strand Thickness – 1.89

Open Area Percentage – 53%

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

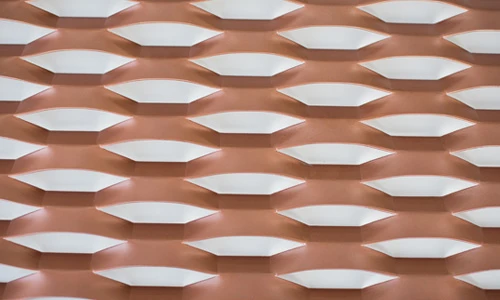

Among the most used meshes in the residential architecture, particularly

suitable to be shaped to create new spaces and new ideas. Let yourself be emotioned by the opportunity of giving space to your imagination.

Technical Details

LWD (mm) – 240

SWD (mm) – 70

Strand Width – 20

Strand Thickness – 1.89

Open Area Percentage – 64%

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

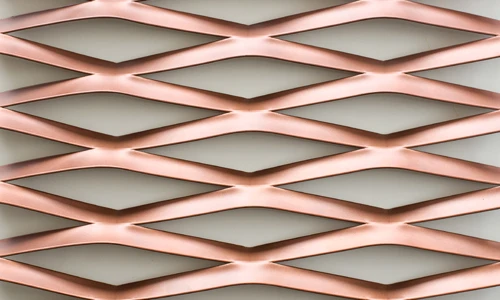

It gives the building an unique elegance thanks to its particular diamond shape. By creating new lines and profiles it is able to model every kind of structure with elegance and originality.

Technical Details

LWD (mm) – 150

SWD (mm) – 50

Strand Width – 18

Strand Thickness – 1.89

Open Area Percentage – 31%

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

The small light passage of this expanded metal allows the realization of most covering but anyway airy spaces. It is particularly suitable when there is a necessity of privacy or security together with a new aesthetic value.

Technical Details

LWD (mm) – 225

SWD (mm) – 35

Strand Width – 12

Strand Thickness – 1.89

Open Area Percentage – 20%

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

The main characteristic of the expanded metal is to play with shadows and lights. Polaris gives the opportunity of having a mesh with big dimensions and a diamond shape open area.

Technical Details

LWD (mm) – 60

SWD (mm) – 30

Strand Width – 6

Strand Thickness – 1.89

Open Area Percentage – 70%

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

Among the most used meshes in the residential architecture, particularly suitable to be shaped to create new spaces and new ideas. Let yourself be emotioned by the opportunity of giving space to your imagination.

Technical Details

LWD (mm) – 72

SWD (mm) – 35

Strand Width – 15

Strand Thickness – 1.89

Open Area Percentage – 32%

Material: Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

E- MESH Expanded Metal Mesh has four architectural views

- A- Side in the direction of expansion

- A- The side opposite to the direction of expansion

- B- Side in the direction of expansion

- B- Side against the direction of expansion

Technical Details

LWD (mm) – 240

SWD (mm) – 70

Strand Width – 20

Strand Thickness – 1.89

Open Area Percentage – 64%

Material : Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

Technical Details

LWD (mm) – 150

SWD (mm) – 50

Strand Width – 18

Strand Thickness – 1.89

Open Area Percentage – 31%

Material : Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement.

Technical Details

LWD (mm) – 225

SWD (mm) – 35

Strand Width – 12

Strand Thickness – 1.89

Open Area Percentage – 20%

Material : Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement.

Technical Details

LWD (mm) – 60

SWD (mm) – 30

Strand Width – 6

Strand Thickness – 1.89

Open Area Percentage – 70%

Material : Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

Technical Details

LWD (mm) – 170

SWD (mm) – 50

Strand Width – 20

Strand Thickness – 1.89

Open Area Percentage – 53%

Material : Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement

Technical Details

LWD (mm) – 72

SWD (mm) – 35

Strand Width – 15

Strand Thickness – 1.89

Open Area Percentage – 32%

Material : Aluminium, Copper, Mild Steel, Galvanized Steel and Stainless Steel

Colour : RAL as per the requirement